Road to data-driven industry: Levels of implementation for creating digital twin

June 04, 2025

Bangladesh is slowly learning the necessity of data transparency, security, and other measures to create a data-centric society that can ensure good governance. Industries also need to embark on this journey of data automation.

Many steel industries, privately owned combined-cycle power plants, a few local home appliance manufacturers, and the pharmaceutical industry are taking such initiatives. They use automation and digitalization tools to realize realistic data and process control benefits.

There are four key phases in the automation and digitalization journey: becoming digital-ready, implementing different levels of automation in processes with ERP integration, implementing AI-enabled digitalization tools, and creating a digital twin of the plant/manufacturing unit.

Becoming digital-ready is the most important and challenging task for Bangladesh’s industries. The reason is primarily the lack of computer literacy in our workforce, mainly at the mid or senior-mid-management levels.

To achieve digital readiness, each operational cycle of an organization should be converted into a data-centric flow diagram. Every text and step should be represented numerically. This leads to the creation of master data templates and a repository.

Microsoft Excel and Access can be the first tools to start with. All officials, from senior to mid-level, need to be proficient in these tools. Once the data collection processes are in place and synced with master data, a trustworthy day-to-day data-centric operation and decision-making network is built.

The next step is to bring automation to the factory. This will enable the factory’s workforce to contribute to the company’s growth rather than being limited to day-to-day monotonous data collection/maintenance tasks.

Automating a factory/industry requires a few levels of planning and implementation. At level 0, PLC or programmable logic controllers are used with some set parameters to control every machine. Siemens, ABB, Mitsubishi, Allen Bradley, Honeywell, etc., are some of the global PLC market leaders present in Bangladesh.

Level 1 is to control a process where multiple machines are controlled through a link of PLCs or DCS (Distributed Control System). For Level-0 and Level-1, machine-level instrumentations need to be checked before going for automation.

For example, the machines might have very old instrumentation/measuring sensors for speed, flow, pressure, etc., which might not be able to feed the data to the latest PLCs. A common issue in many industries is that they might have a rudimentary level DCS or PLC system with a Profibus-based communication protocol.

However, Profibus is no longer the industry standard, and Profinet is the latest technology for industrial Ethernet and communication solutions. Hence, modifications/adaptations and upgrades are necessary for a proper level 1 implementation.

Level-2 automation is implemented for an entire plant/facility/factory. All level-1 PLCs communicate with each other through level-2 servers and maintain the plant’s optimum operation and throughput parameters. Level 2 is the helping hand of the factory’s management team to maintain properly finished output from the plant.

Level 3, with the ERP (Enterprise Resource Planning) integration phase, brings business perspectives and supply chain mechanisms into synch with plant operation. With level-3 automation, raw materials, sales orders, and inventory management are integrated into the plant’s technical operation aspects.

If an industry has completed its journey through the above phases, its operational data governance, day-to-day data collection process and overall database management are well established. It has graduated and is ready for the post-graduation level, which is digitalization and, later, AI-based digital twin creation.

So far, level-3 automation is used for handling real-time data from different process/operation cycles—plant-based or commercial. The data in these processes is not automatically analyzed. Barely any tolerance alarms, flags, or protective shutdowns based on set parameters are functioning.

Digitalization provides management analysis support to bring technical efficiencies or business/profitability growth. It can be achieved with AI-based or historical data analysis-based tools through big data analytics, AI, and machine learning. The process is integrated with market analytical tools like customer relationship management (CRM), like SAP CRM, SalesForce, etc., and human capital management (HCM) tools, like Workday, SuccessFactors, etc.

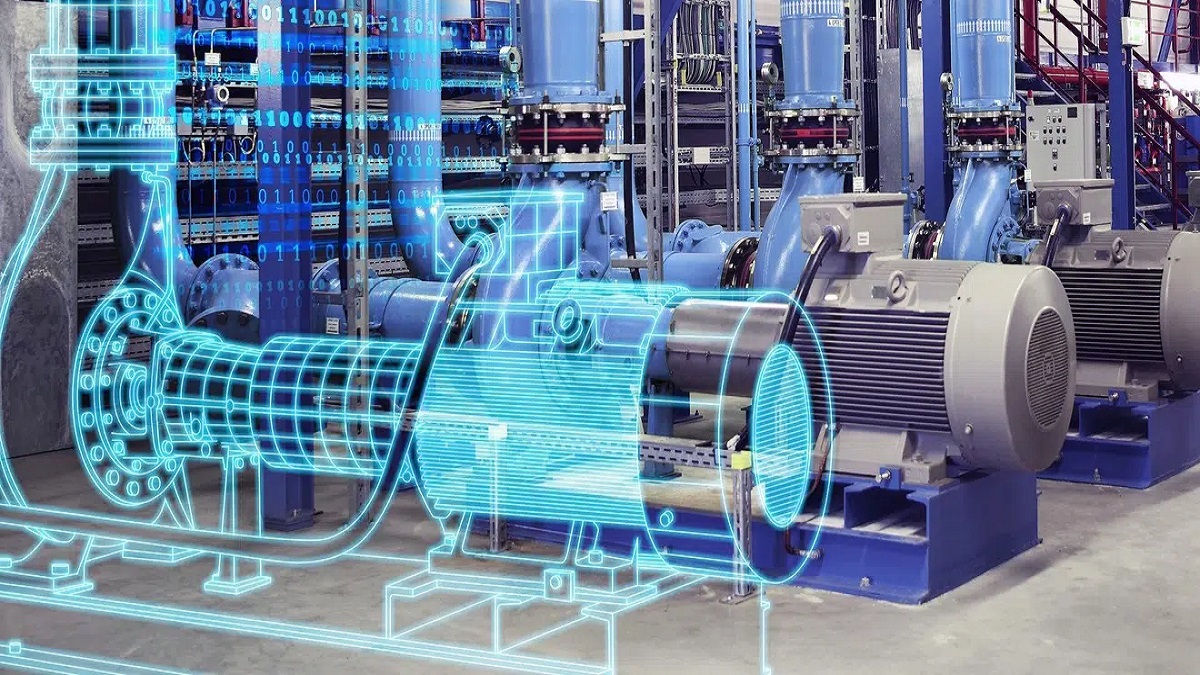

Digital twins can be implemented along with digitalization tools. They create a digital replica of the entire business and plant’s real-time operation, making it easier to monitor, foresee, and control from anywhere. Considering the current overall scenario of our industries, the last two phases can be kept on the wish list but not made mandatory.

Bangladesh needs to develop its workforce capacity first to at least graduate. A key reason for local investors not opting for automation and data management is their heavy dependence on foreign resources. The solution providers of such platforms have only sales offices in our country. All implementing resources are coming from abroad, which makes it lengthy and costly. Hence, investors fear their business might get hampered or paralyzed while implementing such a process.

Even if some of the big organizations are taking such steps, they are always trying to have a manual override that they may control through the field workforce during failures.

The overall transformation approach must be taken holistically. Implementing the system will not pave the way for digitalization or AI-driven operations. Capacity building in the workforce is much needed at this moment in time, and that can also be phased out.

Industries and universities need to collaborate more to create a workforce that will be able to fully support the local market for the first phase and, if not fully, to some extent, the second phase. Business owners need to come forward and take calculated risks; university-industry collaboration can create a feasible environment for that.

Year-on-year projects can be taken to automate and create databases for the industries. Both faculty members and industrial leaders need to plan for such initiatives progressively.

Definite KPIs and yearly goals can drive the objectives. Many reforms and proposals are ongoing at this moment. This is the right time for professional bodies like the Institution of Engineers, Bangladesh (IEB) and the Institute of Cost and Management Accountants (ICMAB) to step up, utilize a positive attitude towards reforms, and begin the process for a revolutionary change in the industries.

Giasuddin M Tauseef is currently the country manager of Bangladesh SMS Group. He is a techno-commercial project professional with an electrical power engineering background. He has over 15 years of experience in heavy industries, especially power generation, distribution, steel, and non-ferrous manufacturing.

Most Read

Electronic Health Records: Journey towards health 2.0

Making an investment-friendly Bangladesh

Understanding the model for success for economic zones

Bangladesh facing a strategic test

Bangladesh’s case for metallurgical expansion

How a quiet sector moves nations

A raw material heaven missing the export train

Automation can transform Bangladesh’s health sector

A call for a new age of AI and computing

You May Also Like